Back to projects

Arm & Hammer Facility

Geotechnical

Location

York County, PA

About

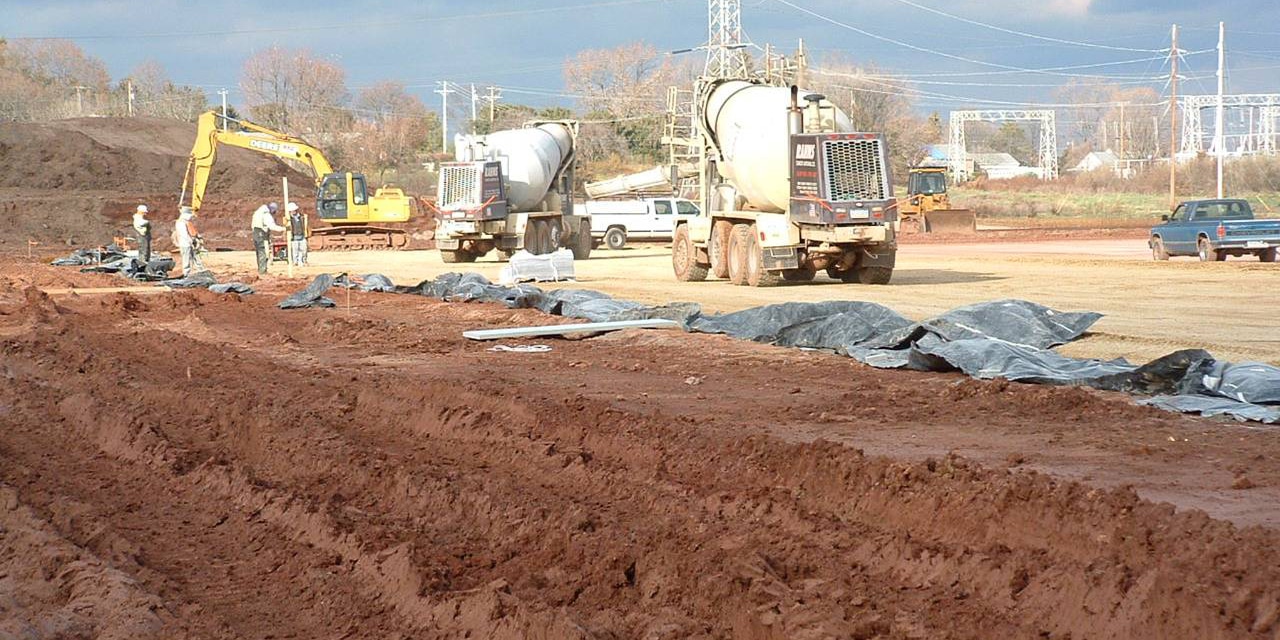

GTA’s geotechnical consultation, value engineering, and construction testing services performed for construction of a 1,100,000-square-foot manufacturing and warehouse facility is a testament to the value that GTA adds to complex projects.

GTA provided value engineering and geotechnical consultation for many problematic soil and geologic conditions encountered during construction. GTA prepared mix designs using lime to stabilize the clayey soils that were used as building pad fill. This allowed the placement of fill through the fall and winter months, which helped keep the project on schedule. Additionally, the lime treated surface layer of the building pad allowed high volumes of heavy traffic to travel on the building pad during the full duration of the project. GTA recommended the use of full depth reclamation (FDR) for the one-half mile long entrance access roadway. The use of FDR resulted in significantly lower pavement costs than full depth removal and replacement. GTA performed pavement design analysis for the 15-acre, 450-space tractor-trailer parking area that will support traffic from over 200 tractor-trailers per day. GTA also provided consultation for areas of shallow groundwater encountered during mass grading and repair of sinkholes encountered in the stormwater basins.

During construction, GTA provided testing of structural fill, utilities, concrete, foundations, precast panels, slabs, masonry, structural steel, and asphalt and concrete pavements. This included over 30,000 cubic yards of concrete placed for the 1,100,000-square-foot floor slab. At times, GTA provided up to four technicians on site working 24 hours a day, to perform the concrete sampling and floor flatness testing.

Explore some of our similar projects here:

Laurel Elementary School

Sportika