Back to projects

Liberty Harbor East

Geotechnical

Location

Baltimore City, MD

About

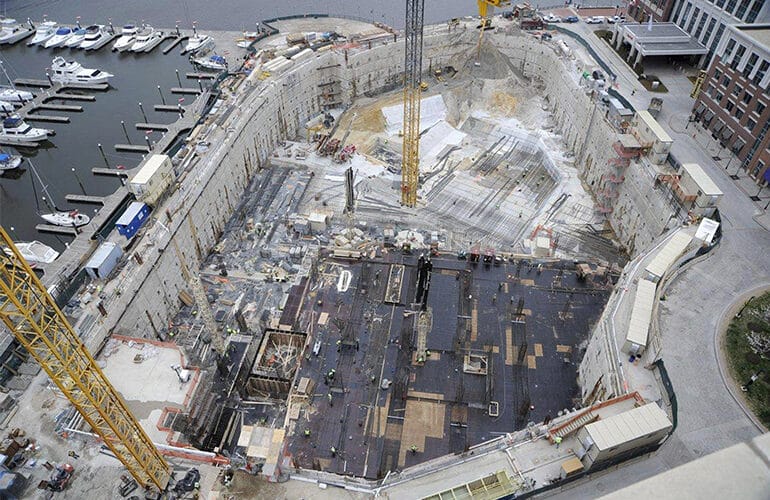

This project is a 23-story, ≈750,000-SF, mixed-use building with retail, parking, apartments and condominiums, located within the Harbor East area of Baltimore City. GTA provided subsurface exploration, geotechnical engineering, Phase I and II Environmental Site Assessments, and construction observation and testing services and environmental consulting during construction of the building’s foundation. GTA’s geotechnical field exploration included 58 soil borings to evaluate subsurface conditions at planned drilled pier foundation elements. Each boring was drilled using hollow stem augers to auger refusal, which was encountered at depths approaching 90 feet. Standard Penetration Test (SPT) borings were performed at intervals of 5-feet throughout each boring. Upon encountering refusal, 5 to 10-foot rock core samples were collect from 31 selected borings.

An additional 18 boreholes were drilled to depths approaching 62 feet for the installation of rod extensometers. Each extensometer included two settlement indicator rods, fitted with anchors at the bottom. The rods were installed to approximately 30 feet and 62 feet in each bore hole. The rod extensometers were grouted in place with a cement-bentonite grout designed to be similar in strength to the soils encountered during drilling. The upper terminus of each extensometer element was fitted with a reference head and electronic measurement equipment, and protected with a waterproof steel vault.

GTA connected 14 settlement monitoring elements to a culvert, which was within 5-feet of planned drilled foundation elements. The monitoring points were installed to detect any settlement of the structure during the drilling and installation of foundation piers for the proposed building. The Culvert is an approximately 6-foot-wide by 3-1/5-foot-high masonry culvert made with brick masonry liner surrounded by approximately 3-foot-wide buttresses made with dry laid granite stone. The structure is supported by timber decking on timber piles, approximately 22 feet long. GTA cored the asphalt and cobble-stone road base, and hand excavated to the top of the culvert. The brick surface of the culvert was carefully cleaned, and a 1-1/2″ steel rod was connected to the brick structure with epoxy. A PVC sleeve was placed over the steel rod to ensure that vertical movement was not inhibited by coming into contact with adjacent soils or debris. The annulus between the PVC sleeve and the excavation was filled with coarse sand, and the upper terminus was completed with a waterproof steel vault.

Explore some of our similar projects here:

Parkside at Warfield

Retaining Wall at Box Hill